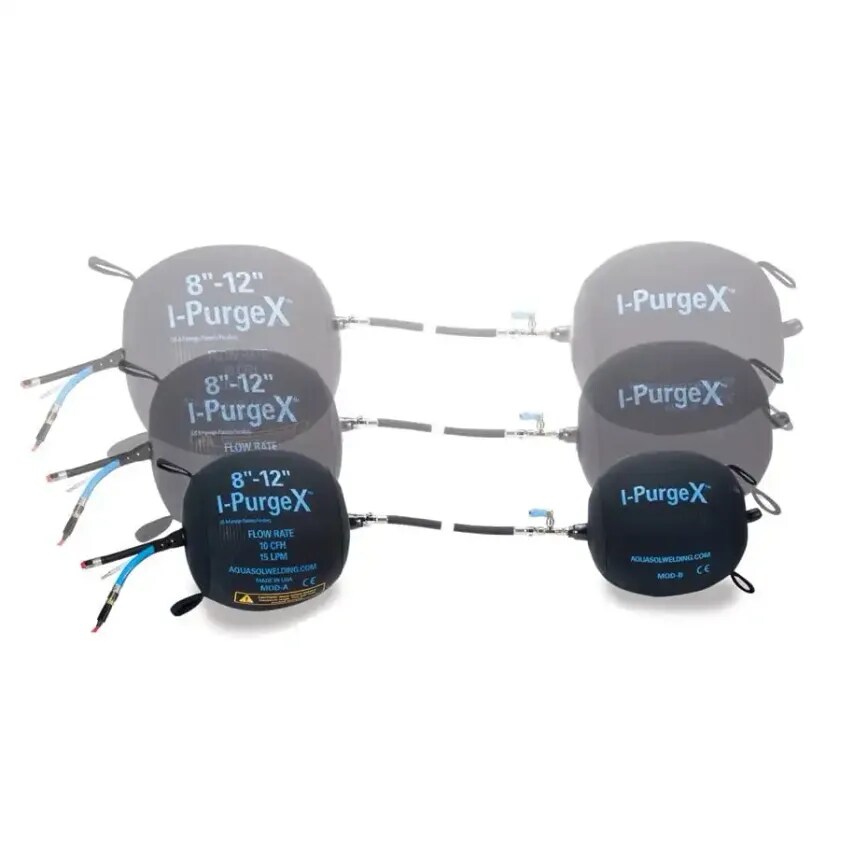

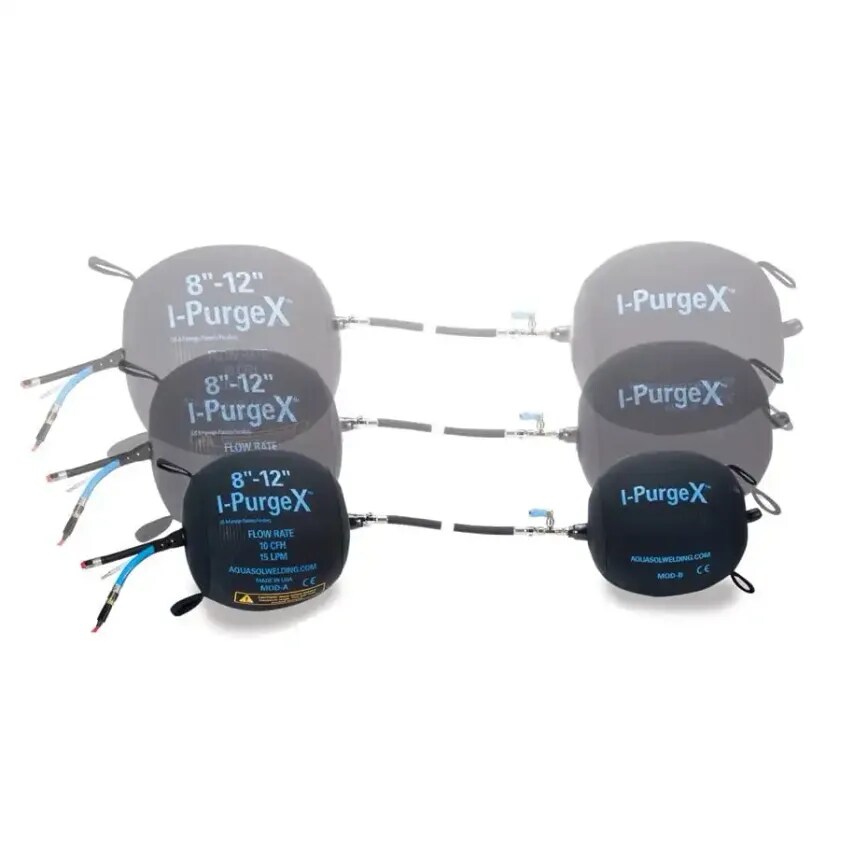

I-Purge X Modular Inflatable Bladder System 356-457mm

Achieve flawless welds with the Aquasol I-Purge X Modular Inflatable Bladder System, the industry's most advanced and versatile pipe purging solution. Designed to meet the needs of even the most demanding welding applications, the I-Purge X system delivers exceptional performance, unmatched versatility, and cost-saving benefits.

Benefits

Achieve consistently high-quality welds

Reduce purge gas consumption and save money

Minimise downtime with quick and easy setup

Protect equipment from heat damage

Enjoy long-lasting performance and versatility

Features

Bladder Expansion Technology (BET): Enables one unit to fit multiple pipe sizes, reducing your inventory and saving money

Quick Connect Fittings: Snap-in place for easy assembly and disassembly, minimising downtime

Extended Length, High Heat Resistant Harness: Allows bladders to be placed outside the heat-affected zone, protecting equipment and ensuring safety

Reusable and Expandable: Built to last, with the ability to expand and fit multiple pipe specifications, maximising your investment.

Application

Pipe purging for welding

Isolating valves and tanks

Sealing pipe systems for servicing, cleaning, and inspection

Instructions

1. Ensure I-Purge X is fully assembled (i.e., modules are securely connected to harness)

2. If necessary, connect rope, chain, or wire to the pull loops on the ends of the bladder modules. This will allow you easy insertion and removal of the system.

3. Connect inert gas lines to the BLUE and BLACK hoses. BLUE gas hose is required to inflate the purge bladders. BLACK gas hose is optional to expedite the purging process.

4. Position the purge unit in the pipe using the luminescent indicator as a guide to center the system across the root gap.

5. Turn the BLUE gas hose on to inflate the bladders and purge the weld zone.

6. Always maintain a consistent flow rate during inflation, purging, and welding.

7. For sizes 2?-36?, BLUE gas hose should transfer inert gas at 30 SCFH (15 LPM) only. For sizes 38?-48?, BLUE gas hose should transfer inert gas at 60 SCFH (28.5 LPM) only.

8. Once a tight seal has been achieved, commence welding.

9. After the weld is complete, turn off the gas supply to deflate the bladders. Once the heat zone has sufficiently cooled, remove I-Purge X from the pipe. Be sure to disconnect all gas lines and monitoring equipment.

10. Clean I-Purge X and store in the provided carrying bag when it is not in use.